研發能力

Chyanfeng's R&D team adopts the synchronous design concept, puts forward our professional suggestions in the process of customer development, and imports the German professional mold design software VAMOS, and uses CATIA's mechanism simulation to perform action and interference analysis to improve the quality of our molds.

In order to develop synchronously with customers, we import CAE computer-aided engineering system and cooperate with reverse engineering technology to find problems in advance and solve them immediately.

The quality of castings depends on whether the Styrofoam mold is well-made or not. For this reason, Qiaofeng Company introduced full-mold Styrofoam solid engraving to improve the precision of the lost foam and the integrity of the appearance.

Manufacturing capacity

Chyanfeng's has excellent manufacturing capabilities for automotive sheet metal parts. Over the years, Qiaofeng has been insisting on introducing high-tech processing software and advanced processing equipment to assist in the production of molds. Cooperating with different processing methods and processing tools can help improve the quality of mold carving and maximize the efficiency. method to complete the assigned task. And has a series of mechanical and hydraulic test equipment of 2000 tons, 1700 tons and 1600 tons.

In order to meet the needs of customers in the production of stamping lines, we have different types of stamping molds such as traditional station molds, precision continuous molds, edge buckle molds, multi-tasking transfer molds, etc., to provide customers with a variety of choices.

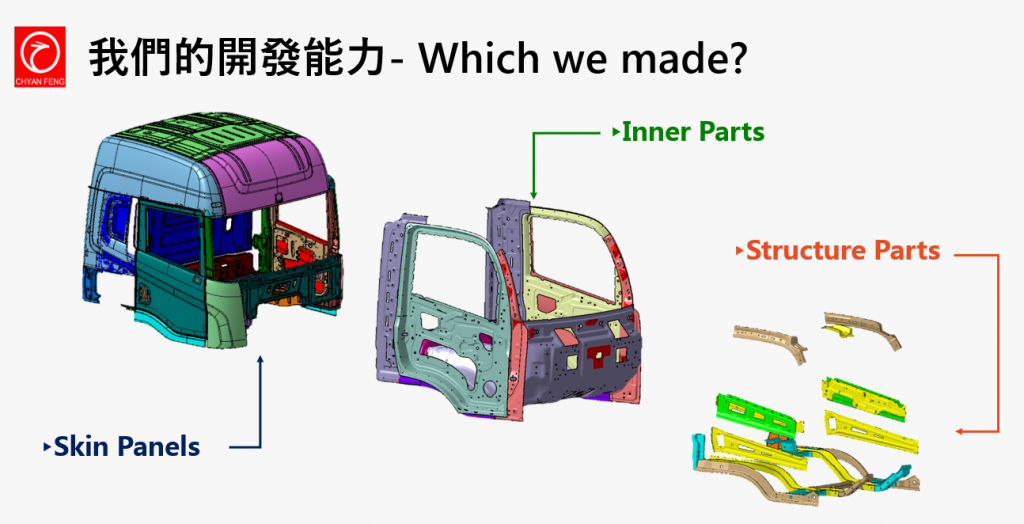

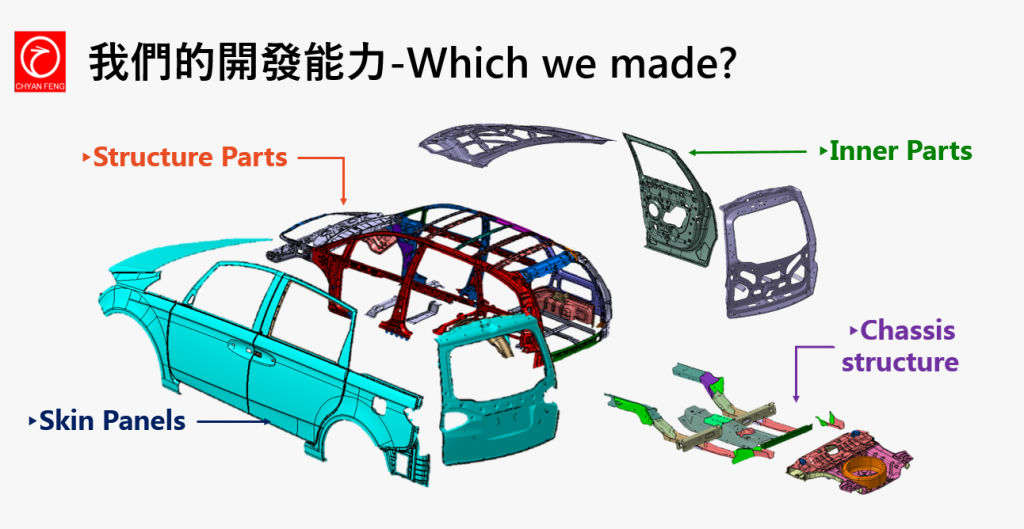

We have production lines of various tonnages ranging from 400 tons to 2000 tons, which can be matched with different mold conditions to make the most suitable production. The use of robot spot welding and hanging spot welding production lines can effectively make up for the tasks that projection welding machines cannot achieve. Diversified product production, including structural parts such as inner and outer panels and beams of the cover body, are satisfied and recognized by customers in terms of quality and delivery time